how to use a refractometer for machine coolant|machine coolant concentration chart : solution By using a refractometer, operators can monitor the concentration of fluids in real-time, allowing for timely adjustments and preventing issues such as tool wear, poor surface finish, and machine downtime.

Nudge the latch handle up to free handle from its lower parked position. The handle will now spring out into its unlocking position. Lift the handle fully upwards to unlock the door.

{plog:ftitle_list}

What is an autoclave? Discover how it works and learn the stages of the autoclave sterilization cycle process.This type of autoclave is used for sterilization purposes. Here are some stats about this autoclave that are important to know: 1. Sterilization chamber volume: 300-500 L 2. Sterilization temperature range: 220 degrees F – 273 degrees F 3. Cost: $57,900 – $12,400 4. Its features include: 4.1. Automatic water shortage . See more

Watch video & learn how to use a refractometer for coolant - learn how to calibrate your refractometer & check coolant concentration with a refractometer!

aflatoxin b1 elisa kit

Your coolant should have a refractometer "ratio" right on the sticker. Or at least on their website. And really, buy a cheapie, make up a "sample" in a gatorade bottle and use that . Watch video & learn how to use a refractometer for coolant - learn how to calibrate your refractometer & check coolant concentration with a refractometer! Your coolant should have a refractometer "ratio" right on the sticker. Or at least on their website. And really, buy a cheapie, make up a "sample" in a gatorade bottle and use that as your baseline, who cares what the units are.

There are two handheld refractometers for use on the shop floor: analog and digital. Most maintenance personnel and machinists are familiar with the analog refractometers: flip-up lens cover, add a drop of coolant, close the lens cover, look through the eyepiece and read the scale.By using a refractometer, operators can monitor the concentration of fluids in real-time, allowing for timely adjustments and preventing issues such as tool wear, poor surface finish, and machine downtime.Using a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface.

Coolants must operate within a specific concentration window to maintain the right amount of lubricity and additive content. Refractometers are instruments used to obtain a °Brix reading, which measures the oil content present in a coolant mixture.

How a Refractometer is used in a machine shop to measure coolant concentration. TheJoelDalloway. 20 subscribers. Subscribed. 16. 5.9K views 7 years ago. Joel Dalloway - .

Maintaining the proper concentration of coolant is essential to ensure consistent machining performance and to prolong the life of the machine and its tools. In this guide, we’ll explain how CNC coolant refractometers work, as well as .

Use a Refractometer. A refractometer is an essential tool for accurately measuring the concentration of your coolant mixture. Here’s how to use it: Calibrate the Refractometer: Before taking any measurements, calibrate your refractometer using distilled water. Measuring your coolant concentration regularly can help you take control of your production to protect performance, profitability, and your operators' working conditions. The concentration of a coolant is usually determined in the field with a handheld refractometer. Watch video & learn how to use a refractometer for coolant - learn how to calibrate your refractometer & check coolant concentration with a refractometer!

Your coolant should have a refractometer "ratio" right on the sticker. Or at least on their website. And really, buy a cheapie, make up a "sample" in a gatorade bottle and use that as your baseline, who cares what the units are.There are two handheld refractometers for use on the shop floor: analog and digital. Most maintenance personnel and machinists are familiar with the analog refractometers: flip-up lens cover, add a drop of coolant, close the lens cover, look through the eyepiece and read the scale.

By using a refractometer, operators can monitor the concentration of fluids in real-time, allowing for timely adjustments and preventing issues such as tool wear, poor surface finish, and machine downtime.Using a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface. Coolants must operate within a specific concentration window to maintain the right amount of lubricity and additive content. Refractometers are instruments used to obtain a °Brix reading, which measures the oil content present in a coolant mixture.How a Refractometer is used in a machine shop to measure coolant concentration. TheJoelDalloway. 20 subscribers. Subscribed. 16. 5.9K views 7 years ago. Joel Dalloway - .

Maintaining the proper concentration of coolant is essential to ensure consistent machining performance and to prolong the life of the machine and its tools. In this guide, we’ll explain how CNC coolant refractometers work, as well as .

Use a Refractometer. A refractometer is an essential tool for accurately measuring the concentration of your coolant mixture. Here’s how to use it: Calibrate the Refractometer: Before taking any measurements, calibrate your refractometer using distilled water.

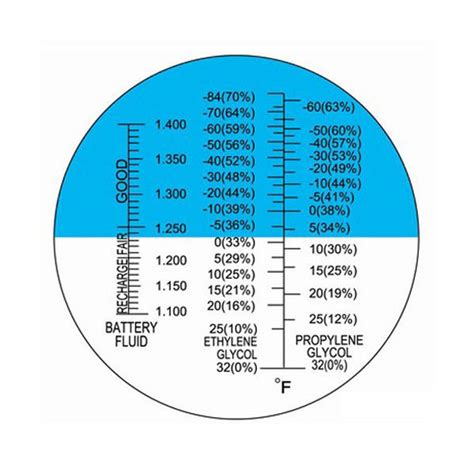

refractometer reading chart

refractometer for coolant concentration

Cell disruption is often suggested as a necessary step to increase the carotenoids or lipid recovery yield by several fold. Therefore, although it introduces additional processing cost, the .

how to use a refractometer for machine coolant|machine coolant concentration chart